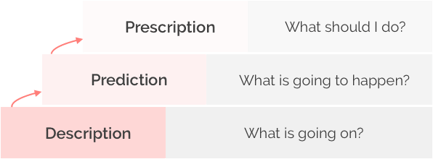

The framework of analytics capabilities - distinguishing between descriptive, predictive and prescriptive analytics - is well known:

This popular representation suggests a progression: from simple to complex, static to dynamic, beginner to expert...

But for continuous intelligence applications, the relationship between prediction and prescription is much richer: you really can't prescribe if you don't predict.

Part 1 of this article (below) discusses the three main reasons for this. Part 2 describes two strategies for integrating predictions and prescriptions.

1. Predictions provide legitimacy to prescriptions

Streaming data is one of the defining features of continuous intelligence. And due to the nature of time series, the ability to predict an event stream is the only robust proof that you understand it: since time dependencies are integral to the challenge, you must be able to capture them.

No ifs or buts.

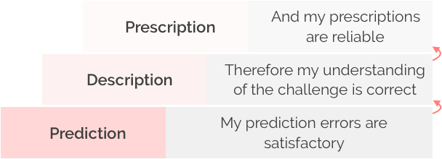

This reshuffles our analytics capabilities framework a bit:

Constantly updated prediction errors tell you how accurate your representation of the phenomenon is, thus how legitimate your prescriptions are.

2. Predictions factor in real-world uncertainty

There are two traditional methods for generating business prescriptions.

- Business rules: They capture an organization's experience, operational constraints and compliance requirements, and translate them into simple prescriptions. "Alert the operator when this threshold is crossed", "start resupplying when inventory reaches that volume", "check that gauge every 12 hours"...

- Optimization: Using a specialized algorithm (there are dozens of them), computing the combination of factors that maximizes/minimizes a business objective. For example: given my production schedule, inventory capacity, cost of capital, lead time, transportation costs and constraints, working capital constraints... how much raw materials should I buy now?

Both methods are quite deterministic, and there are two ways to factor in real-world uncertainty.

- Stochastic simulation, where the factors of the optimization challenge are given random values - generating multiple optimal outcomes ("scenarios") that you can then assess from a business perspective. Very interesting, but more adapted to periodic performance reviews that to high-frequency decisions.

- The combination of prediction and prescription, using one of the two strategies that are reviewed in Part 2 of that article.

3. Predictions ensure that prescriptions are time-consistent

The problem with classic rule- or optimization-based prescriptions is that while each of them may be optimal, nothing ensures the optimality of their sequence. That may be acceptable for low-speed challenges, but not in continuous intelligence situations.

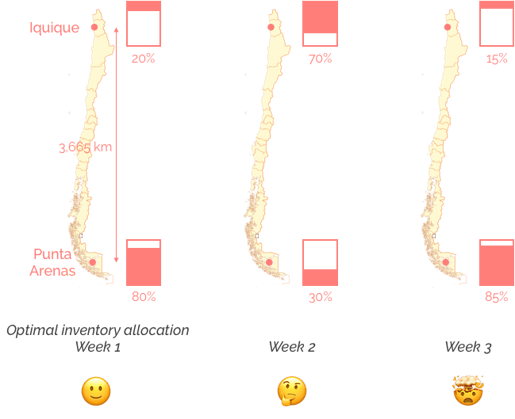

Let's illustrate this with an extreme example of inventory allocation:

- Operating in Chile (4,270 km North to South)

- Warehouses in the beautiful towns of Iquique in the North and Punta Arenas in the South (distance = 3,665 km)

- Allocating inventory every week based on last week's data

It is obvious that taking local demand predictions into account would smooth inventory levels across warehouses over time, and reduce transportation costs. Batch weekly optimals are meaningless - it's continuous optimization that matters.

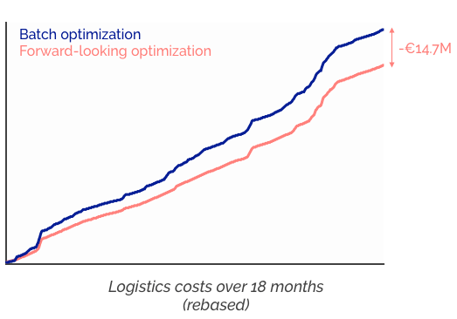

A couple of years ago, a food and beverage company used the Datapred modeling engine for a real-life test of "continuous optimization". The goal was to allocate water bottles across 577 storage areas in a large European country. The following graph shows (over 18 months) the company's cumulated logistics costs in two situations:

- Batch optimization - each day, computing that day's optimal inventory allocation, based on past and present data.

- "Forward-looking" optimization - adding continually updated demand predictions to the optimization model's daily inputs.

Over the test period, time-consistent prescriptions reduce logistics costs by 15% (€14.7M) compared to discrete prescriptions.

***

Part 2 of this article describes two strategies for integrating predictions and prescriptions (both pre-packaged in the Datapred modeling engine). Don't hesitate to contact us for questions. You can also visit this page for a list of external resources on continuous intelligence.